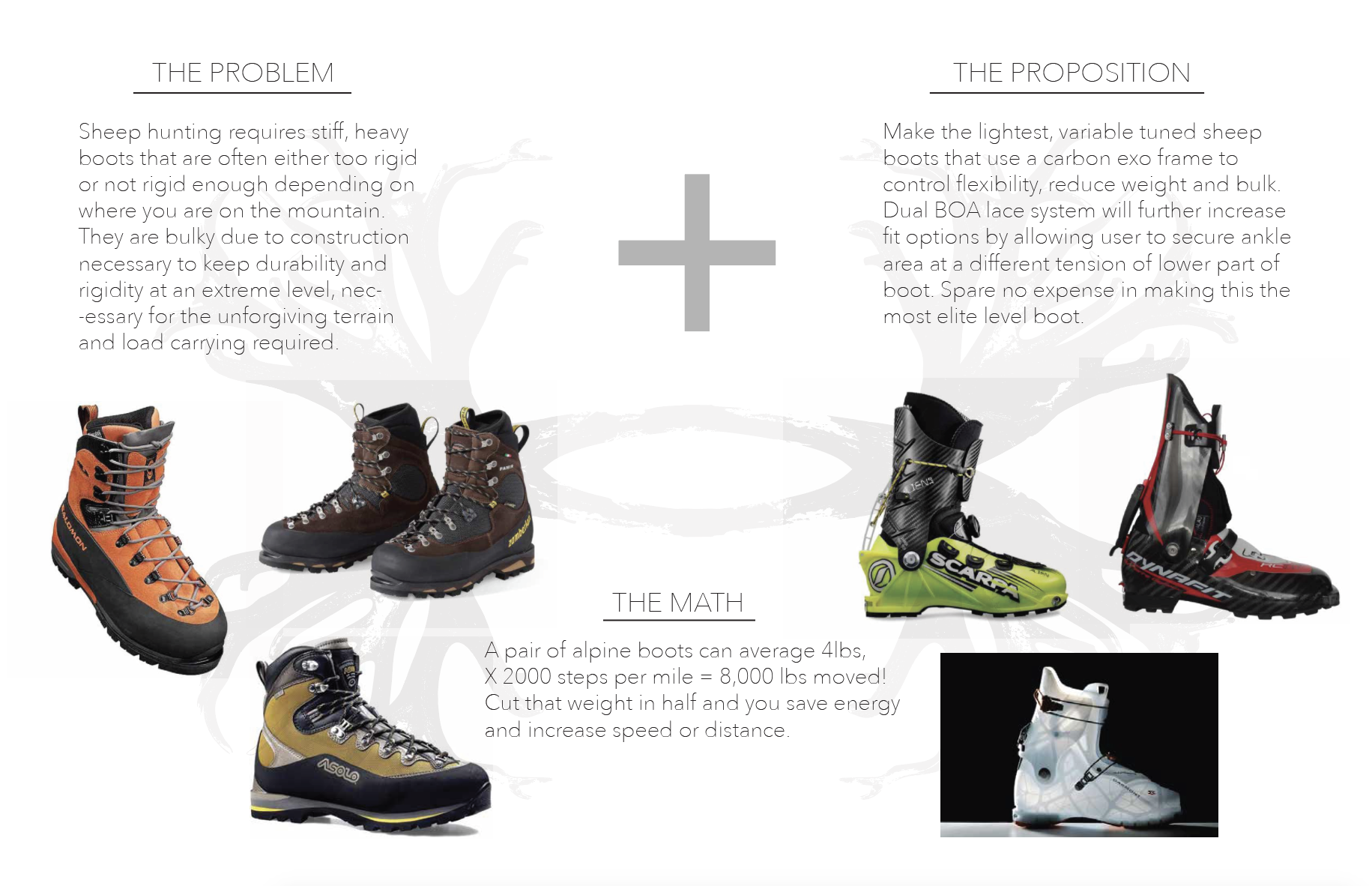

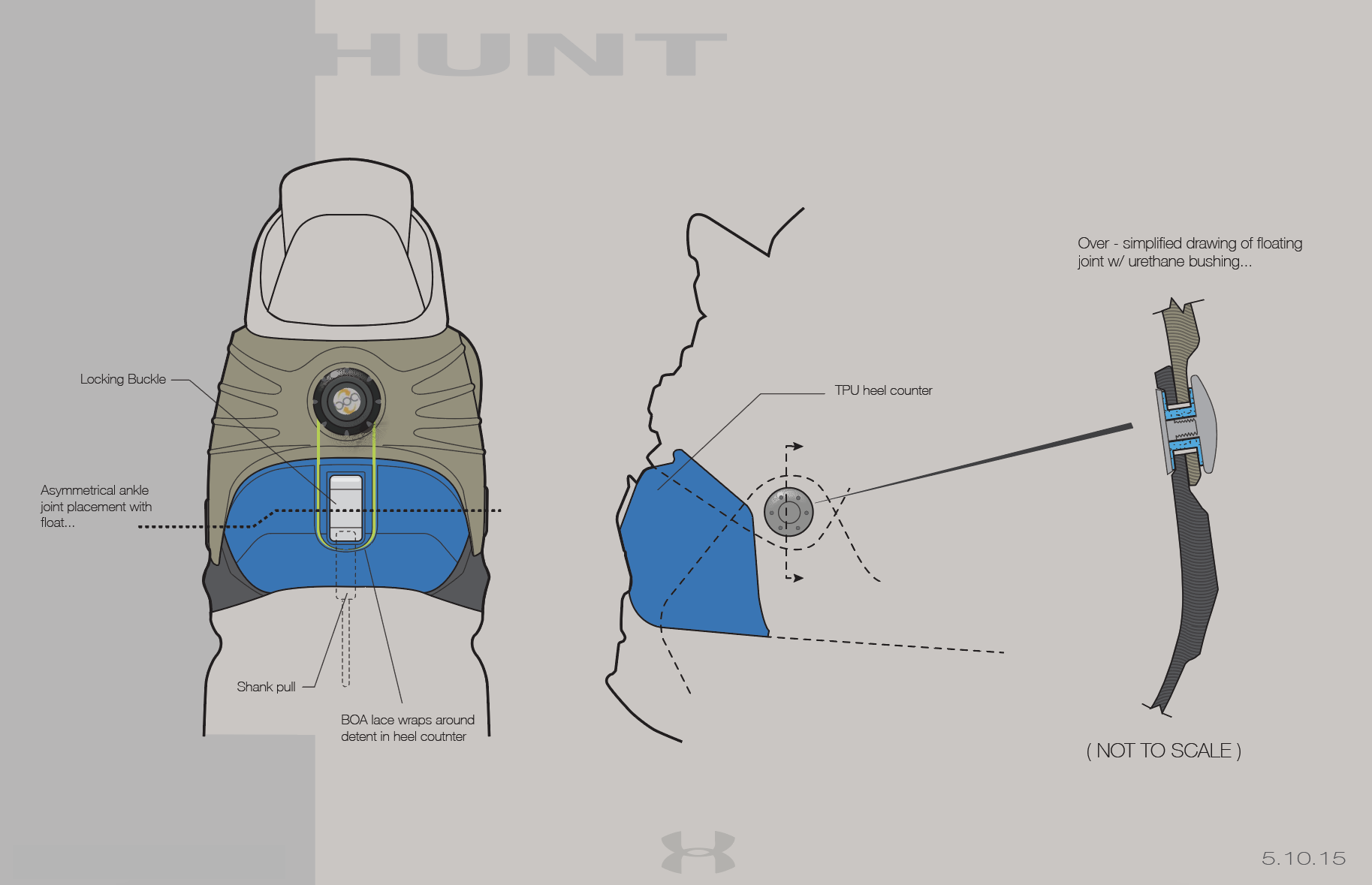

This is a project for one of our co-founders at UA, who like myself has a passion for the outdoors and bow hunting. Alpine boots are stiff and heavy for a reason. Your life can depend on them. The user needs to be a able to transfer weight into incredibly small areas of the outsole for edging on small rock protrusions by limiting flex in the tooling. I won’t get into the details here but its done in a number of ways that traditionally add weight. As well, these stiff boots while great on slabs and steep terrain, work against the user on the approach or lower terrain areas where they have to overcome the stiffness of the boot which acts as a giant lever. We came up with the idea of a hybrid boot that would allow for an adjustable shank stiffening element as well as a chopped, compression-molded carbon fiber skeleton to support the upper. This would allow the wearer to dial in more less stiffness and flexibility with a BOA dial while removing unwanted weight everywhere else. The midsole and outsole were existing from an inline boot another designer had done, with Vibram rubber and I wanted to use it as a base as it was working well. We made it to 3D and used this as inspiration for an inline boot that allowed us to shave 2lbs off a pair of boots without sacrificing stiffness. We only made it as far as a model, very complicated with multiple parts.

*I have better pics coming…